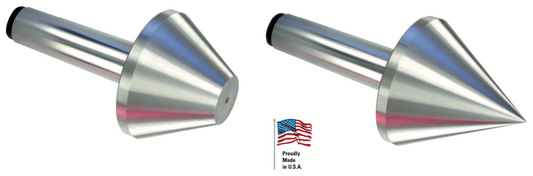

Collection: Royal Live Centers

Proudly made in the the U.S.A.! Royal live centers are widely regarded by top metalworking professionals as the best live centers available anywhere in the world. Each Royal live center is a finely crafted tool, incorporating the highest quality steels, bearings, lubricants and seals. Manufactured to exacting tolerances, Royal live centers are guaranteed accurate to +- 0.00005" TIR or better.

Royal Products offers a broad range of standard live center models to suit virtually all turning applications. They also design and build hundreds of custom centers each year to meet special customer requirements. Custom live centers from Royal Products are competitively priced and are held to the same high manufacturing tolerances as our standard models. Please contact us any time to discuss a custom live center to meet your needs.

-

Royal Off-The-Shelf "Special" Live Center

Regular price From $1,145.00 USDRegular priceUnit price / per -

Royal High-Precision Quad-Bearing Live Center

Regular price From $1,050.00 USDRegular priceUnit price / per -

Royal High-Precision CNC Quad-Bearing Live Center

Regular price From $1,020.00 USDRegular priceUnit price / per -

Royal Heavy-Duty Spindle Type Live Center

Regular price From $877.00 USDRegular priceUnit price / per -

Royal Heavy-Duty CNC Spindle Type Live Center

Regular price From $923.00 USDRegular priceUnit price / per -

Royal High-Speed Precision Live Center

Regular price From $1,360.00 USDRegular priceUnit price / per -

Royal Spring Type Live Center

Regular price From $976.00 USDRegular priceUnit price / per -

Royal Ultimate Multi-Tasking Live Center

Regular price $1,750.00 USDRegular priceUnit price / per -

Royal Versa-Turn Live Center

Regular price From $722.00 USDRegular priceUnit price / per -

Royal Standard Pipe and Bull Head Live Center

Regular price From $1,295.00 USDRegular priceUnit price / per -

Royal Changeable-Point Live Center

Regular price From $1,110.00 USDRegular priceUnit price / per -

Individual Points for Royal Changeable-Point Live Centers

Regular price From $178.00 USDRegular priceUnit price / per -

Royal "Oil Country" Big-Bore Bull Head Live Center

Regular price From $995.00 USDRegular priceUnit price / per