Royal CNC Bar Pullers

Overview

Royal CNC bar pullers can be used to easily automate any CNC lathe or turning center. Bar pullers improve productivity by enabling CNC lathes to run unattended, freeing up operators to handle other tasks. Royal CNC bar pullers are inexpensive, require minimal setup, and can be easily fit to any CNC lathe.

Royal bar pullers have a number of advantages over bar feeders:

- Bar pullers are much less expensive. The average cost of a Royal bar puller is $600, compared to $10,000 - $30,000 for a bar feeder.

- Royal bar pullers are easier to setup and use - no electrical interface with the machine tool control is required.

- Bar pullers don’t waste valuable floor space.

- Bar pullers can be easily moved from machine to machine as jobs require.

- Royal bar pullers offer maintenance-free operation.

Additional Information:

Royal Compact CNC Bar Pullers

- The Royal Compact CNC Bar Puller is designed for use on all CNC lathes, but is particularly well-suited for use on small machines where tool interference may be an issue.

- Flexible heat-treated steel fingers provide strong grip force for pulling round, hex and square stock.

- Unit comes standard with serrated jaws and one blank spindle bushing. Smooth jaws are available for pulling soft materials.

- Proudly Made in U.S.A.

Royal Heavy-Duty CNC Bar Pullers

- The rugged, heavy-duty construction of this bar puller model holds up under the most demanding manufacturing conditions.

- The Royal Heavy-Duty CNC Bar Puller is very easy to setup and use, and is capable of pulling round, hex, and square stock up to 6.5" in diameter.

- Heavy internal die springs provide very high grip force, making this the strongest bar puller on the market.

- Available in square and round shank versions.

- Proudly Made in U.S.A.

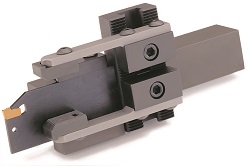

Royal Combo CNC Bar Pullers

-

The Royal Combo CNC Bar Puller is both a bar puller and a cut-off tool in one unit. Benefits of this design include:

- Saving a turret station by combining two tools into one.

- Reduced cycle time becuase the turret does not need to index between the cut-off and pulling operations.

- The Royal Combo CNC Bar Puller is designed for use on all CNC lathes, and is very easy to setup and use.

- Flexible heat-treated steel fingers provide strong grip force for pulling round, hex and square stock.

- Unit comes standard with serrated jaws and one blank spindle bushing. Order cut-off tool and insert separately.

- Royal offers Kennametal tooling, but the Combo Bar Puller is compatible with all major brands of cut-off holders and inserts.

- Proudly Made in U.S.A.

Royal Coolant-Actuated CNC Bar Pullers

- The patented Grippex 20L CNC Bar Puller is actuated by a CNC lathe's coolant system. As coolant is fed through the unit, it pushes a piston forward which causes the fingers to close down on the bar stock. When the coolant is turned off, the fingers automatically spring open.

- With this bar puller, no adjustment by the operator is necessary - the fingers simply close down until they contact the bar. This feature is especially useful for making multiple pulls on the same workpiece, even after the OD has been turned.

-

The Grippex Coolant Actuated Bar Puller is also useful as a part loader/unloader. When fitted with special jaws, this tool can:

- Remove finished parts from a machine's subspindle and place them into the parts catcher. This eliminates the need for unreliable ejectors and enables the subspindle to swallow longer parts.

- Remove a bar remnant and drop it in the parts catcher for disposal. This prevents the remnant from falling into the chip conveyor where it could become jammed and cause damage to the conveyor.

- The Royal Grippex Bar Puller achieves very high gripping force through a patented finger mechanism that pivots on roller bearings. As little as 15 psi of coolant pressure is enough to enable the Grippex to pull a 210 lb. bar!

- Unit can also be operated by air pressure for custom applications.